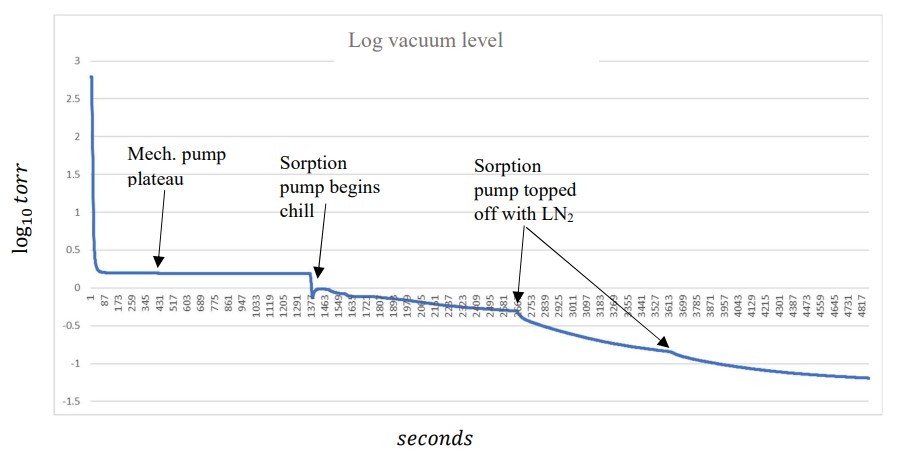

Cryogenic test 1/5/22

The objectives for this test were to verify leaks which we had previously fixed, test the operation of our new pneumatic isolation valve, and test our ion gauge. We met the first two of these objectives, but struggled with outgassing. A recent freeze introduced a lot of water into the vacuum system (including the mechanical pump oil, which Reed Michael replaced) and we need to bake out the entire system before the next test.

Vacuum profile for this test

The system during this test

Other aspects of the test:

1) We transitioned the pneumatic valve from running off a CO2 bottle to running off a bottle of welding gas (the supply we had at that moment).

2) We improved the data logging function of the control box, allowing us to easily access live vacuum data. This also allows us to view particular gauge outputs, opening up an avenue for more sophisticated leak testing.

3) As we chased the outgassing issue (initially believing it was a leak), we verified that particularly suspect joints were, in fact, tightly sealed.

4) We waxed shut the mechanical pump NPT connections, eliminating yet another leak.

Preparations for the next test:

1) Bake out the entire vacuum system – but particularly the sorption pump.

2) Replace home-made LN2 reservoir with vacuum insulated vessel (which Reed Michael is currently figuring out how to manufacture).

3) Service mechanical vacuum pump to achieve better initial vacuums.

4)Develop a way to leak test in a way similar to helium leak testing. Previously unknown gauge functionality should allow us to do this (we bought out gauge used, and we had very little information as to its functionality. Some extra functions we have since discovered are working).

5) Quantify the amount (and quality of) zeolite in the sorption pump so we can compare actual performance to theoretical performance.